Your Position: Home - Products - Concrete Auxiliary Equipment - Concrete Pumps -

- What is the capacity of the concrete mixer do you need?

- What is the height or length distance you want to deliver the concrete?

- How big the maximum aggregate size in the concrete?

- Which type do you prefer? Electric motor driven or diesel engine driven?

If you know the above information, please contact us by email or online service and leave your contact information. Our professional salesman will contact you within 24 hours to discuss about the solution with you.

25-33m Concrete Boom Pump

HMC5025 Truck Concrete Pump Boom

Small and Medium Concrete Pump

XBS/DXBS Fine Stone Concrete Pump

Concrete Mixer Pump

Truck Mounted Concrete Pump

Introduction

Small and medium concrete pump, using advanced technology of concrete pump in the world, it is the first advanced floor heating construction equipment in domestic and suitable for construction of large area, high efficiency in pea gravel concrete packing layer or mortar packing layer of floor heating engineering. Adopting international famous brand spare parts, reasonable design and high stability, greatly improving working efficiency and reducing labor intensity. This product sell to major cities nationwide and get good market response, win the high praise of our customers. Selling first in domestic for three consecutive years.

Performance

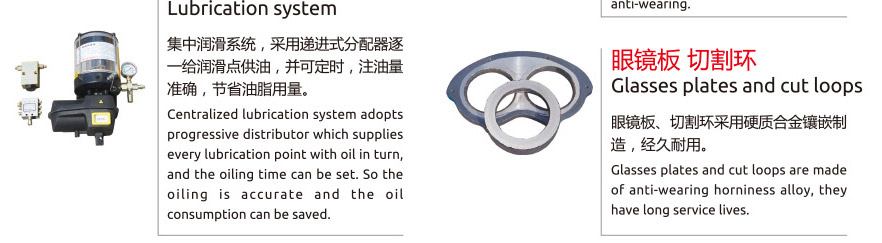

1. Distribution valve adopts the advanced S pipe value system,with good sealing performance,simple and reliable structure,and easy replacement of wearing parts;

2. S pipe is equipped with floated wearing ring, compensating attrition automaticly, good tightness.

3. The counterforce on specially designed “S” valve is received by hopper wall to assure the service life of goggle plate and cutting ring.

4. Outlet pressure is high, which satisfy the high building construction and long distance transmission requirements.

5. Hydraulic system adopts U return circuit, reversing is fast and efficient.

6. Hydraulic oil cooling adopts advanced air cooling system, it do not need connect water source and easy to use.

7. Reverse pumping function can facilitate cleaning the conveying pipe.

8. Automatic lubricant filling device can eliminate the trouble of manual filling and extend the service life of the parts with less abrasion in the lubricants.

9. Most electrical appliance components of electrical system are imported, and PLC for control system,with reliable working,strong adaptability,and wired remote control;

10.Electric case is equipped with wired remote control handle.

Specification

| Item | Unit | Electromotor series | Diesel series | |||

| HBT40 | HBT50 | DHBT40 | DHBT50 | |||

| Theoretic concrete delivery volume | M3/h | 40 | 50 | 40 | 50 | |

| Theoretic concrete delivery pressure | Mpa | 10 | 12 | 10 | 12 | |

| Hydraulic pressure | Mpa. | 25 | 28 | 25 | 28 | |

| The type of distribution valve | - | S tube valve | ||||

| Electromotor(diesel)power | Kw | 45 | 55 | 56 | 56 | |

| electromotor(diesel) rated speed | r/min | 1480 | 1480 | 2200 | 2200 | |

| Main oil pump | - | Japanese Kawasaki | ||||

| Main cylinder di./pole dia. Stroke | mm | φ100/70×1000 | φ125/80×1200 | φ100/70×1000 | φ125/80×1200 | |

| Diameter of delivery cylinder | mm | φ600×1000 | φ200×1200 | φ160×1000 | φ200×1200 | |

| Capacity of hyfrulic oil tank | L | 200 | 240 | 200 | 240 | |

| Hopper capacity | L | 450 | 600 | 450 | 600 | |

| Overall weight | Kg | 3200 | 3500 | 3400 | 3700 | |

| Dimension(L×W×H) | mm | 4970×1680×1800 | 5270×2000×1840 | 4970×1680×2580 | 5270×2000×2620 | |

| Max. delivery distance | Vertical | m | 120 | 150 | 120 | 150 |

| Horizontal | m | 300 | 350 | 300 | 350 | |

Global Case

HZS100 Concrete Batching Plant in Saudi ArabiaCOUNTRY : Rabigh, Saudi Arabia

HZS50 Concrete Batching Plant in BangladeshCOUNTRY : Bangladesh

YHZS50 Mobile concrete batching plant in RussiaCOUNTRY : Russia

HZS120 Concrete Batching Plant in RussiaCOUNTRY : Russia